This month, Simon Jenkins, who covers the North London area, provides advice on installing floorcoverings over calcium sulphate screeds.

I recently visited a large residential development, consisting of multiple apartment blocks. The flooring contractor who sought our advice was tasked with installing floorcoverings in apartments on a number of floors in three different buildings (over 120 residences in total), and the cement-based levelling compound that they had already applied had begun to detach from the screed below in many areas.

Common concerns

The issue was that the subfloors were calcium sulphate screed – a now frequent choice in new builds because of the speed with which it can be applied over large areas and quicker drying times compared with concrete. There’s also the option to force-dry the screed, which takes as little as seven days.

However, these screeds require a few special considerations when it comes to subfloor preparation, and they’re a frequent topic of question for us because not undertaking certain procedures when working over them is a common cause of floor failure.

For example, the application of cement-based levelling compounds over calcium sulphate screeds can result in a chemical reaction that causes the formation of ettringite, a crystalline material that can cause the two layers to separate. This was likely a contributing factor in this situation, given the presence of multiple different cement-based levelling compounds.

Closer inspection

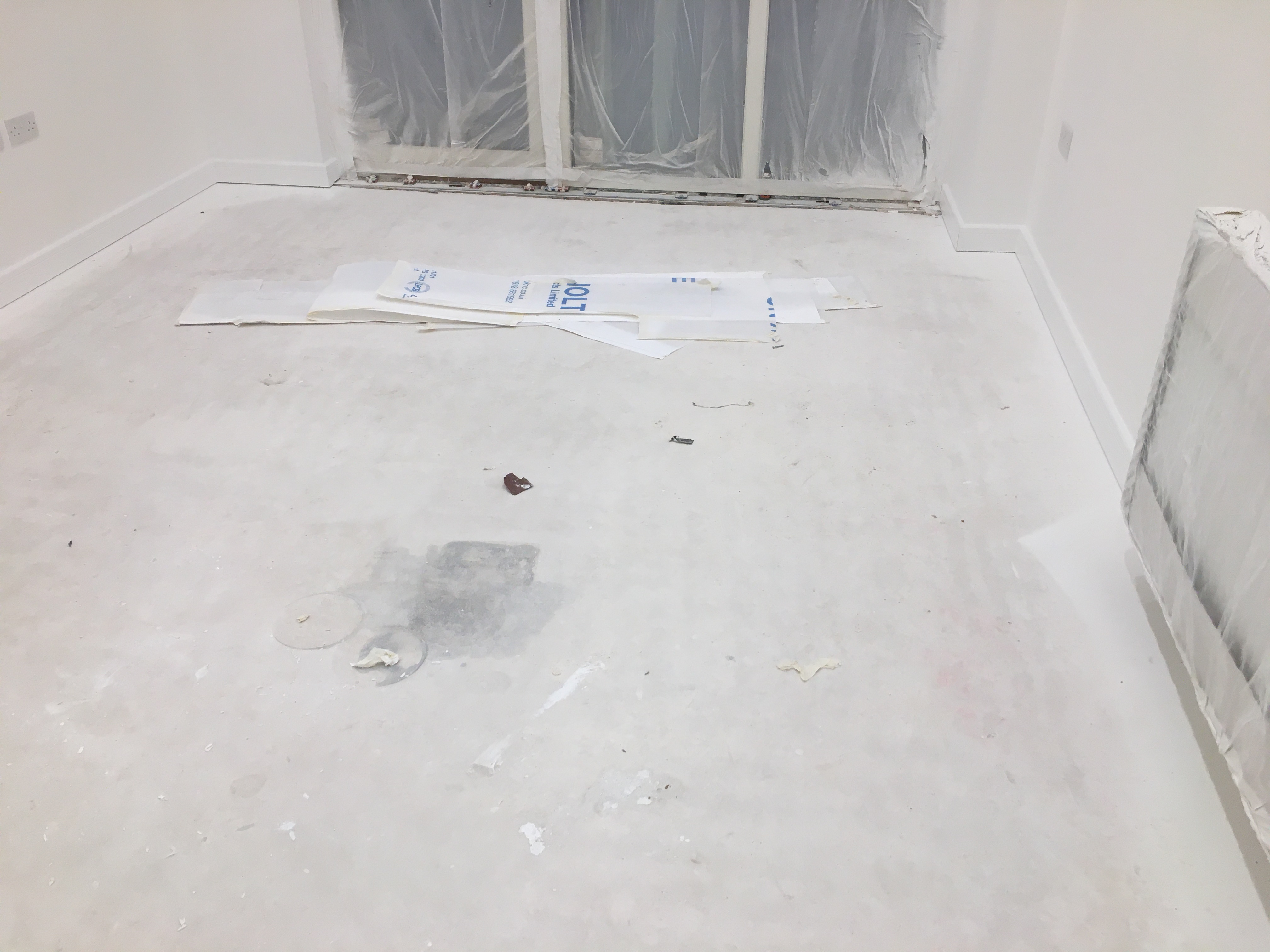

A closer inspection of areas where a levelling compound hadn’t yet been applied revealed that, although they appeared to be sound, the calcium sulphate screeds were contaminated with paint overspray at the edges.

Laitance (the crust of cement and fine aggregates formed on the surface of the screed as it dries) was also found. It should have been removed by the screed installer, but it wasn’t, as is often the case.

Moisture check

As recommended as part of any floorcovering installation, we also undertook a moisture test to see if subfloor relative humidity levels were low enough for floorcoverings to be installed. In the first instance, a handheld radio frequency moisture meter was used to check for the presence of subfloor moisture, giving readings of 230-299, where above 200 is considered ‘at risk’.

Therefore, a digital hygrometer was used, in accordance with British Standards BS5325 and BS8203, to accurately measure subfloor relative humidity levels, which were found to be above the 75% maximum threshold for installing floorcoverings. Apart from attacking adhesives and causing floorcoverings to debond, excess subfloor moisture can also promote the production of ettringite.

Recommendations

If not removed, both laitance and contaminants, such as paint, grease and oil, can cause subsequently applied levelling compounds to debond from the substrate, potentially causing floor failure. So it was advised that the laitence was mechanically removed, along with other contaminants and cement-based levelling compounds, before proceeding with the flooring installation.

Once the base had been allowed to dry naturally to the point where a test with a hygrometer confirmed that subfloor relative humidity levels were below 75%, the surface could be primed using two coats of F. Ball’s Stopgap P121 primer. It is specially formulated to promote the application characteristics of compatible levelling compounds when applied over calcium sulphate screeds.

Finally, it was recommended that Stopgap 1100 Gypsum, F. Ball’s calcium sulphate-based levelling compound, was applied to create a smooth base for floorcoverings. The application of a calcium sulphate-based levelling compound, rather than a cement-based one, eliminates the possibility of ettringite forming and causing floor failure.

Once the levelling compound had cured, contractors could proceed with installing floorcoverings using a compatible flooring adhesive.

Simon Jenkins is F. Ball technical representative for North London

F. Ball’s regional technical representatives provide advice to flooring contractors on how to get the most out of F. Ball products, including conducting site visits and producing case-specific reports advising on the best course of action for particular flooring projects. Find out who your technical representative is here.